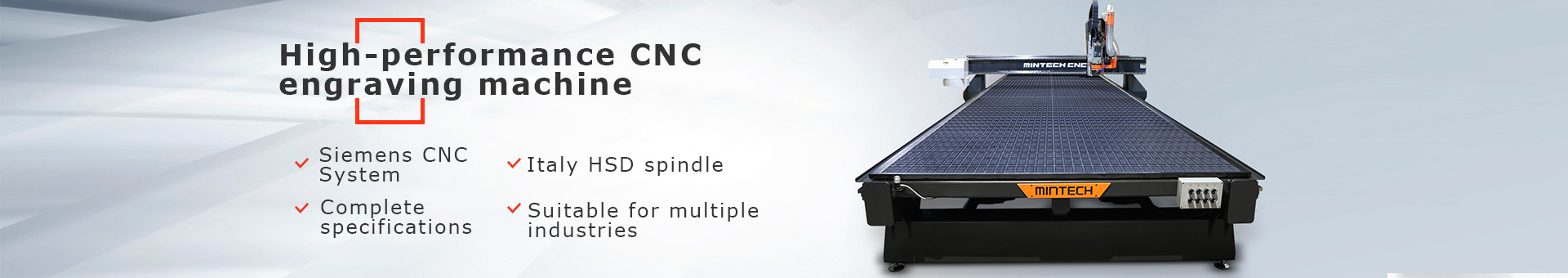

Performance advantages: heavy-duty frame structure, three-axis grinding rack rotation, high-speed, high-precision, and heavy-load processing

Meterial applications: Acrylic, various plastic materials, electronic insulation materials, bakelite, copper-aluminum panels, aluminum-plastic panels, etc.

Industry applications: Acrylic products, architectural decoration, tooling and fixtures, engineering plastics, vehicle interiors, aluminum processing industries, etc.

Model: SR100

Power supply: AC220V / 50HZ / 3PH

Working size: 1270mm * 2540mm * 100mm

Z-axis Clearance: 200mm

Z-axis Traverse: 450mm

Max processing speed: 20m/min

Rapid Traverse: 30m/min

Repeatability : + /-0.05mm

Trasmission: X, Y grinding grade helical rack, Z axis adopts high-precision ball screw drive.

Control System:

1. The control system can choose Weihong control system, Syntec system, Siemens system

2. Tool compensation function:Support tool radius compensation and length compensation through manual and automatic two modes of measurement, easy-to-understand human-computer interaction interface, allowing users to reduce the conversion of tool compensation values. For users who use tool length compensation, many unnecessary conversions are avoided.

Cutting spindle:

1. Spindle motor: Italy HSD 9KW ISO30

2. Spindle speed: 4000-24000RPM

3. Splint specification: SK16

4. Cooling : use maintenance-free independent fan cooling to reduce maintenance

5. Spindle noise: idling less than 65 decibels

Working table:

1. The working table is made of phenolic composite material to ensure the flatness of the working table.

2. Adopt high efficiency vacuum table,any part of the worktable can quickly absorb the work piece.

3. Vacuum pipe adopts double filtration to avoid failure due to vacuum pump inhalation of chips.

Straight-line tool library:

1. Adopts straight-line tool library of 5 tools

2. Tool change speed block with protection function to prevent dust and misoperation, avoid tool change failure

3. Tool library is installed on the cross beam, effectively reducing the movement of the work surface during the tool change process, reduce unnecessary movement and extend the life of the machine.

Industry application:

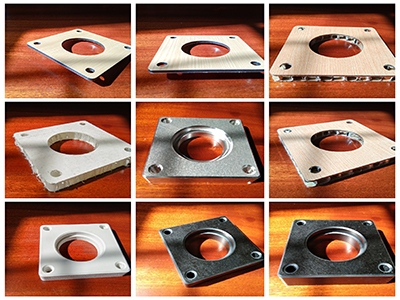

Customer case:

|

NO |

content |

|

Specification |

|

1 |

Processing range |

X axis processing range |

1270mm |

|

Y axis processing range |

2540mm |

||

|

Z axis processing range |

100mm |

||

|

2 |

Machine parameter index |

X, Y, Z axis motion positioning accuracy |

0.05mm/300mm |

|

X, Y, Z repeat positioning accuracy |

0.05mm |

||

|

Maximum moving speed |

30m/min |

||

|

Maximum processing speed |

20m/min |

||

|

Total weight |

About 2500KG |

||

|

Power supply |

AC380V/50HZ/3PH |

||

|

3 |

Workbench |

Phenolic Panel Workbench |

Vacuum adsorption table |

|

Workbench load |

1000KG |

||

|

4 |

CNC system |

Weihong Professional CNC System |

NK300CX |

|

5 |

Tool change system |

Straight-line |

5 tool positions (disc type tool library is optional) |

|

6 |

Drive power (AC servo) |

X axis drive motor |

Delta (optional Yaskawa, new generation bus, Siemens syntec) |

|

Y axis drive motor |

Delta (optional Yaskawa, new generation bus, Siemens syntec) |

||

|

Z axis drive motor |

Delta (optional Yaskawa, new generation bus, Siemens syntec) |

||

|

Voltage |

AC380/3PH |

||

|

7 |

Electric spindle (frequency conversion) |

Spindle |

Italian HSD air-cooled (Mintech or Italian Hiteco can be selected) |

|

Spindle speed |

4000—24000RPM |

||

|

Spindle power |

9 KW |

||

|

Spindle taper |

ISO30 |

||

|

Spindle dynamic balance level |

G2.5 |

||

|

Frequency converter |

VFD |

||

|

8 |

guide |

X axis guide |

Square rail (25mm) |

|

Y axis guide |

Square rail (35mm) |

||

|

Z axis guide |

Square rail (25mm) |

||

|

9 |

transmission |

X axis transmission |

YYC grinding grade helical rack |

|

Y axis transmission |

YYC grinding grade helical rack |

||

|

Z axis transmission |

TBI ball screw |