Laser cutting opens a new chapter in wooden furniture

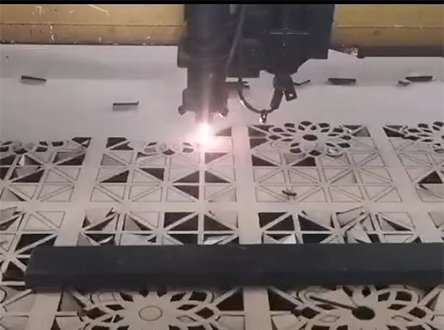

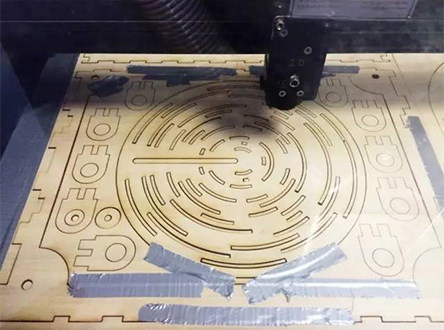

【Case summary】:In recent years, with the continuous development and improvement of the laser industry, the practicality of laser cutting technology has also continued to increase, and has gradually begun to be applied to the wooden furniture industry, replacing the original time-consuming and labor-intensive manual engraving with exquisite cutting and hollowing processes. , Inject new vitality into modern wooden home decoration. |

In recent years, with the continuous development and improvement of the laser industry, the practicality of laser cutting technology has also continued to increase, and has gradually begun to be applied to the wooden furniture industry, replacing the original time-consuming and labor-intensive manual engraving with exquisite cutting and hollowing processes. , Inject new vitality into modern wooden home decoration.

1. The working principle of laser processing wood

Laser engraving mainly uses high-energy-density laser beams to convert heat energy, which instantly causes thermal decomposition and carbonization of wood, thereby removing part of the material.

2. Advantages of laser engraving

Laser engraving is a non-contact processing method. Compared with traditional mechanical processing methods, laser engraving has the advantages of no sawdust pollution, no tool wear, no need to change tools, and no noise pollution (very low noise).

3. The working method of laser engraving wood

A Cutting and engraving

The cutting method is used to process the required pattern on the surface of the wooden material, that is, the pattern is first decomposed and expressed into a number of line forms, and then these lines are cut by a laser, and then the pattern represented by the cutting line is obtained.

B Engraving

Cut the pattern part, and leave the wood material surface intact on the outer part of the pattern

C Punch carving

Contrary to the concave mold engraving, this engraving process only cuts off the material on the periphery of the pattern, and the cutting force is the same at each point, but the material of the pattern itself is not cut. This kind of engraving method is suitable for the expression of characters, figure outlines, etc.

For specific details, please call our service hotline: 138-2577-9334. Dongguan Mintech Electronics Co., Ltd. (brand: Mingte) is located in Hengbang Science and Technology Park, Niushan Industrial Zone, Dongguan City; the company covers an area of 5,000 square meters and is a high-tech enterprise focusing on R&D, production and sales. The main products are There are laser cutting machines , aluminum plate cutting machines, aluminum plate engraving machines and so on. Welcome to consult.