The perfect combination of CNC engraving machine and shipbuilding

【Case summary】:Prospects for marine aluminum plates With the development of lightweight transportation, aluminum plates are increasingly used in transportation vehicles such as yachts, ships, RVs, and functional transportation vehicles. The processing and use of aluminum plates in these industries is increasing rapidly, and the prospects are great! Common marine aluminum plates Commonly used marine aluminum plates are 5052 aluminum plates, 5083 aluminum plates, and 5086 aluminum plates. The state is mainly h111, h112, and h321. The thickness of marine aluminum plates is determined by the hull structure, ship specifications and use parts, etc. The commonly used plates are There are thin plates over 1.6mm and thick plates over 30mm. |

The application of aluminum plate in the boat industry

Prospects for marine aluminum plates With the development of lightweight transportation, aluminum plates are increasingly used in transportation vehicles such as yachts, ships, RVs, and functional transportation vehicles. The processing and use of aluminum plates in these industries is increasing rapidly, and the prospects are great! Common marine aluminum plates Commonly used marine aluminum plates are 5052 aluminum plates, 5083 aluminum plates, and 5086 aluminum plates. The state is mainly h111, h112, and h321. The thickness of marine aluminum plates is determined by the hull structure, ship specifications and use parts, etc. The commonly used plates are There are thin plates over 1.6mm and thick plates over 30mm.

As the application of aluminum plates in the shipbuilding industry becomes more and more extensive, the amount of aluminum plate processing is gradually increasing, which indirectly causes the demand for aluminum plate processing equipment to continue to rise. How can I choose a high-quality aluminum plate engraving machine market in this mixed aluminum plate engraving machine market? The equipment does require some effort.

Aluminum hull

Q1Can the CNC engraving machine process aluminum plates?

A: Aluminum plates of various thicknesses can be cut, drilled, tapped, and chamfered by CNC engraving machines.

Q2 How to achieve a better aluminum plate processing effect?

A: If a worker wants to do his job well, he must first sharpen his tools!

Choosing a suitable CNC engraving machine is a good start. The aluminum plate processing industry must choose an industrial-grade CNC machining center.

01

Machine body

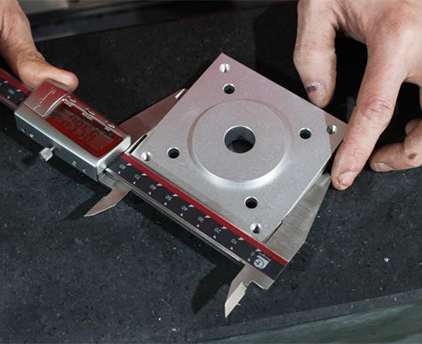

(Reasonable structure, solid materials, process flow, precision machining)

02

Configuration is king

(CNC control system, drive transmission system, core power spindle)

Siemens bus or Taiwan's new generation system

Germany or Taiwan transmission device

Italy frequency conversion spindle 03

Assembly process (details determine success or failure)

Q3How to process aluminum plate with CNC engraving machine ?

1. Design and layout according to customer requirements, calculate the path correctly, and save the file.

2. Copy the file to the DSP handle. (If you use a control card machine, please open the control card software, read in the layout, and save the file).

3. Fix the material, define the origin, start the spindle, and adjust the spindle speed.

4. Turn on the power, the machine will reset and self-check, the X, Y, and Z axes will return to the zero point, and then run to their initial positions.

5. Adjust the X, Y, and Z axes separately, align the origin of the engraving work, and adjust the spindle speed, feed speed, and Z axis height appropriately to make the engraving machine enter the work waiting state.

6. Open the engraving file and transfer the file to the engraving machine to automatically complete the engraving work of the file.

7. When the engraving file ends, the engraving machine will automatically lift the knife and move to the top of the starting point of the work.

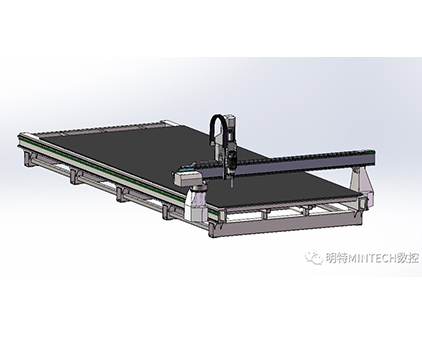

Mingte CNC engraving machine SR2080

Dimensions: 9000*2860*2100mm

Working range: 2000*8000mm control system Siemens spindle motor

9KW automatic tool change air cooling

Spindle speed: 4000-24000RPM

Performance characteristics: simple operation, complete functions, good engraving and cutting effects, and fast speed

Adapted plate: aluminum plate, aluminum-plastic plate

Industry application: aluminum processing industry, etc.