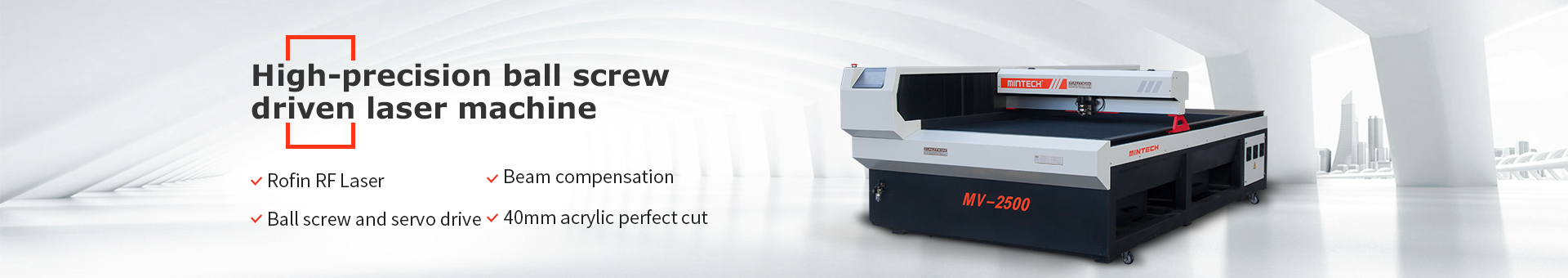

Performance advantages: thick sheet metal structure, aluminum profile precision milling guide surface, servo drive, screw drive, high-precision and high-quality cutting

Material applications: acrylic, various plastic materials, electronic insulation materials, wood boards and other non-metallic boards

Industry applications: Acrylic products, architectural decoration, craft gifts, electronic films, fabrics and leather materials, etc.

Model: MC2500

Power supply: AC220V / 50HZ / 2PH

Working size: 1250mm * 2500mm

Max processing speed: 20m/min

Repeatability: + /-0.05mm/300mm

Laser tube: Optional glass tube 100W, 150W, 180W, 200W, 300W or RF laser

Driving mode: X, Y, Z axis adopt high-precision ball screw drive.

Laser performance:

1. Metal-encapsulated beam combining laser, stable for long-term work without deformation, stable performance, and long overall sealing life;

2. Installing a new beam combining device, with good beam quality, better spot, and faster cutting speed;

3. Laser Endoscopes all use the products of the US 26 company, the highest standard in the industry, and the average life span is more than 2 years, which is more than twice that of other products;

4. Standardized interfaces of the products can be interchanged arbitrarily.

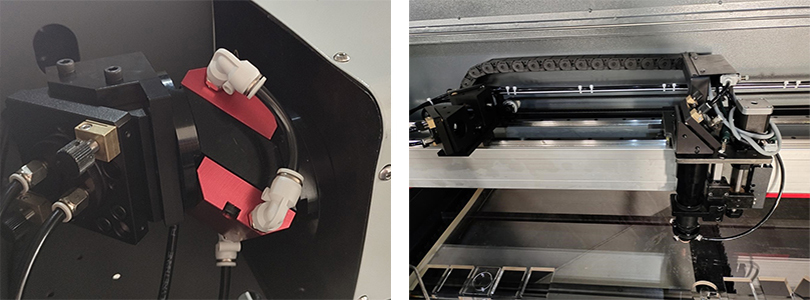

Light path system:

All have patented optical path combining technology, which is configured in the optical path system, constant optical path and lens cooling system

Water cooling system: Teyu or Tongfei

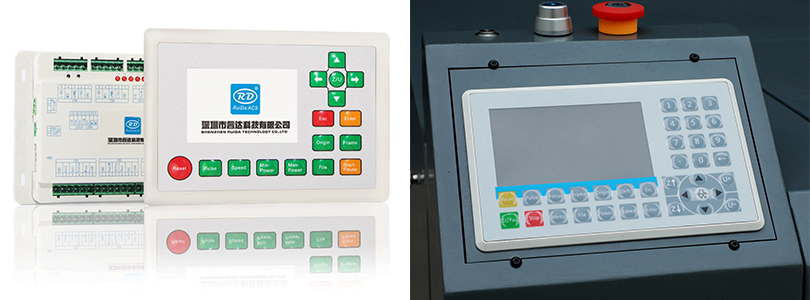

Control system: Ruida CO² laser control system, stable performance and simple operation

Transmission system: Taiwan TBI guide rail and screw

Drive system: Japan Mitsubishi servo drive and motor

Cutting sample:

Customer Testimonials:

|

Content |

|

Remark |

|

Laser power |

100W、150W、180W、200W、300W |

Glass tube, RF laser can be used |

|

Dimensions |

3600×1900×1300mm |

|

|

Working area |

X:1250,Y:2500mm |

High-precision machining center processing |

|

Idle speed |

20m/min |

|

|

X/Y axis positioning accuracy |

±0.05 |

mm/m(mm/m) |

|

X/Y axis repeat positioning accuracy |

±0.05 |

mm |

|

Power supply |

220V 10A |

|

|

Acrylic maximum cutting thickness |

30mm |

Perfect cut |

|

Cutting head |

Long focus and short focus fast switching precision cutting head |

Independent research and development |

|

Flying light path |

Flying light path design |

Equipped with constant light path and cooling system |

|

Mechanical transmission system |

X/Y axis adopts ball screw |

Taiwan imports |

|

X/Y/Z adopts TBI guide rail |

Taiwan imports |

|

|

Dedicated cooling system |

Temperature control accuracy up to ±0.5℃, multiple alarm protection functions

|

Special domain or co-fly |

|

Sport control |

Ruida CO² Laser Control Card |

Optional CCD edge patrol system |

|

Server Driver |

MITSUBISHI |

Mitsubishi Japan |

|

Main contactor |

LS |

South Korea |

|

Main solenoid valve |

SMC |

Japan |

|

Origin switch |

PANASONIC |

Japan Matsushi |

|

Machine wiring |

Highly flexible towline cable |

Shanghai Yichu |

|

Fan |

1.5KW |

|