your current location:

your current location:

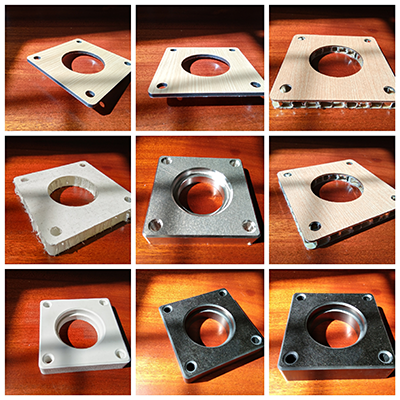

Performance advantages: complete functions, good engraving and cutting effects, high precision, cost-effective processing tool for high-quality processing

Adapt to the board: Acrylic, various plastic materials, electronic insulation materials, bakelite, copper-aluminum panels, aluminum-plastic panels, etc.

Industry applications: acrylic products, advertising production, tooling and fixtures, engineering plastics, aluminum processing industries, etc.

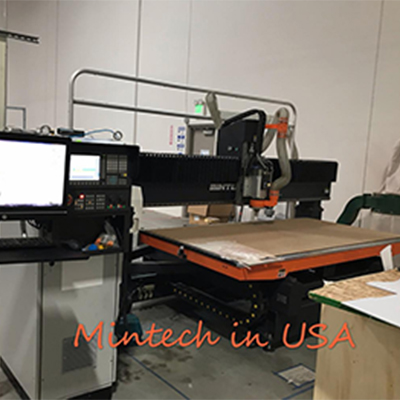

Model: V8

Working voltage: AC380V / 50HZ / 3PH

Machinable size: 1270mm * 2540mm * 100mm

distance from beam to table surface: 200mm

Z axis stroke: 450mm

Maximum processing speed: 20m/min

Maximum moving speed: 30m/min

Repeat positioning Accuracy: + /-0.05mm

Drive mode: X, Y, and Z axes are driven by high-precision ball screws.

The control system adopts Weihong control system.

Tool compensation function.

Spindle motor: 9KW ISO30 Motorized spindle

spindle speed: 4000-24000RPM

Chuck specifications: SK16

Cooling method: use maintenance-free independent fan cooling, reduce maintenance

spindle noise: idling less than 65 decibels

The work surface is made of phenolic composite material board to help ensure the flatness of the processing table.

The high-performance grid-shaped vacuum table is used. Any part of the work table can quickly adsorb the workpiece. The

vacuum pipeline adopts double filtration to avoid the failure of the vacuum pump sucking chips.

Adopt 8-tool disc tool magazine

tool change speed block, with protection function to prevent dust and misoperation, avoid tool change failure. The

tool magazine is installed on the beam, which effectively reduces the movement of the work surface during the tool change process, reduces unnecessary movement, and extends Machine life

|

NO |

content |

|

Specification |

Remark |

|

1 |

Processing range |

X axis processing range |

1270mm |

|

|

Y axis processing range |

2540mm |

|

||

|

Z axis processing range |

200mm |

|

||

|

2 |

Machine parameter index |

X, Y, Z axis motion positioning accuracy |

0.05mm/300mm |

|

|

X, Y, Z repeat positioning accuracy |

0.05mm |

|||

|

Maximum moving speed |

30 m/min |

|||

|

Maximum processing speed |

20 m/min |

|||

|

Total weight of machine tool |

About 3000KG |

|||

|

Working voltage of machine tool |

AC380V/50HZ/3PH |

|||

|

3 |

Workbench |

Phenolic Panel Workbench |

Vacuum adsorption table |

|

|

Workbench load |

500KG |

|

||

|

4 |

CNC system |

Weihong Professional CNC System |

NK280 (continuable new generation or Siemens CNC system) |

|

|

5 |

Tool change system |

Row style |

8 pockets |

|

|

6 |

Drive power (AC servo) |

X axis drive motor |

Delta (optional Yaskawa) |

|

|

Y axis drive motor |

Delta (optional Yaskawa) |

|

||

|

Z axis drive motor |

Delta (optional Yaskawa) |

|

||

|

Voltage |

AC380/3PH |

|

||

|

7 |

Electric spindle (frequency conversion) |

Spindle |

Air-cooled (optional Italian HSD or Hiteco) |

|

|

Spindle speed |

4000—24000RPM |

|

||

|

Spindle power |

9KW |

|

||

|

Spindle taper |

ISO30 |

|

||

|

Spindle dynamic balance level |

G2.5 |

|

||

|

Frequency converter |

VFD |

|

||

|

8 |

guide |

X axis guide |

Square rail (25mm) |

|

|

Y axis guide |

Square rail (35mm) |

|

||

|

Z axis guide |

Square rail (25mm) |

|

||

|

9 |

transmission |

X axis transmission |

Ball screw rod |

|

|

Y axis transmission |

Ball screw rod |

|

||

|

Z axis transmission |

Ball screw rod |

|