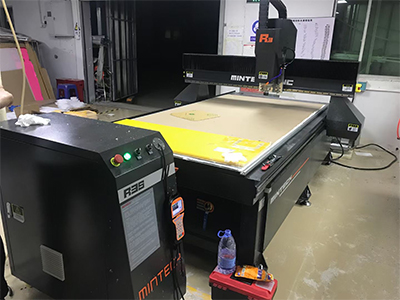

Performance advantages: simple operation, complete functions, good engraving and cutting effect, entry-level preferred product

Adapt to the board: acrylic, wood, various plastic materials, electronic insulation materials, bakelite, aluminum, aluminum-plastic panels, etc.

Industry applications: acrylic products, advertising production, architectural decoration, engineering plastic parts, vehicle interiors, etc.

Model: R3

Dimensions: 3000×2120×1900mm

Machinable size: 1300mm ×2500mm × 60mm

Working voltage: AC380V / 50HZ / 3PH

Distance from beam to table surface: 150mm

Z-axis stroke: 160mm

Maximum processing speed: 10m/min

Maximum idling speed: 15m /min

Repeat positioning accuracy: + /-0.05mm

Drive mode: X and Y axis adopt helical gear rack drive; Z axis adopts high precision ball screw drive

Control System:

1. The control system adopts Minte control system

2. Hand-held operation box

Cutting spindle:

1. Spindle motor: 6KW manual tool change

2. Spindle speed: 4000-24000RPM

3. Chuck specification: ER25

4. Cooling method: air cooling

working desk:

1. The work surface adopts composite material board to ensure the flatness of the processing surface; T-slots are installed on both sides to facilitate the clamping of the workpiece.

2. Using high-efficiency grid-shaped vacuum table, equipped with a vacuum pump, any part of the worktable can quickly adsorb the workpiece.

3. The vacuum pipeline adopts double filtration to avoid failure due to the suction of chips by the vacuum pump.

Industrial applications:

Customer case:

|

NO |

content |

|

Specification |

|

1 |

Processing range |

X axis processing range |

1300mm |

|

Y axis processing range |

2500mm |

||

|

Z axis processing range |

60mm |

||

|

2 |

Machine parameter index |

X, Y, Z axis motion positioning accuracy |

0.05mm/300mm |

|

X, Y, Z repeat positioning accuracy |

0.05mm |

||

|

Maximum moving speed |

15m/min |

||

|

Maximum processing speed |

10m/min |

||

|

Total weight of machine tool |

About 1500KG |

||

|

Working voltage of machine tool |

AC380V/50HZ/3PH |

||

|

3 |

Workbench |

Phenolic Panel Workbench |

Four-zone vacuum adsorption table |

|

Workbench load |

200KG |

||

|

4 |

CNC system |

Minte professional CNC system |

Handle (optional computer interface or other numerical control system) |

|

5 |

Tool change system |

Manual tool change |

|

|

6 |

motor |

X axis drive motor |

Leisai Servo Drive (other servo systems are optional) |

|

Y axis drive motor |

Leisai Servo Drive (other servo systems are optional) |

||

|

Z axis drive motor |

Leisai Servo Drive (other servo systems are optional) |

||

|

|

|

||

|

7 |

Electric spindle (frequency conversion) |

Spindle |

Air-cooled, manual tool change spindle (water-cooled spindle is optional) |

|

Spindle speed |

24000RPM |

||

|

Spindle power |

6KW |

||

|

Spindle taper |

ER25 |

||

|

Spindle dynamic balance level |

G2.5 |

||

|

Frequency converter |

Ivnt |

||

|

8 |

guide |

X rail |

Taiwan high quality guide rail |

|

Y axis guide |

Taiwan high quality guide rail |

||

|

Z axis guide |

Taiwan high quality guide rail |

||

|

9 |

transmission |

X axis transmission |

Taiwan high-quality helical rack |

|

Y axis transmission |

Taiwan high-quality helical rack |

||

|

Z axis transmission |

Taiwan high-quality ball screw |