Instructions for using pp sheet cutting machine

【Case summary】:The pp sheet cutting machine is a kind of cutting equipment that we commonly use now. It can cut but not limited to the cutting machine pp sheet. The sheet processed by the sheet cutting machine has a more excellent performance ability. With the development of the modern machinery processing industry, the requirements for cutting quality and precision are constantly improving, and the requirements for improving production efficiency, reducing production costs, and having high-intelligence automatic cutting functions are also increasing. Today, let's take a look at the instructions of our pp sheet cutting machine. |

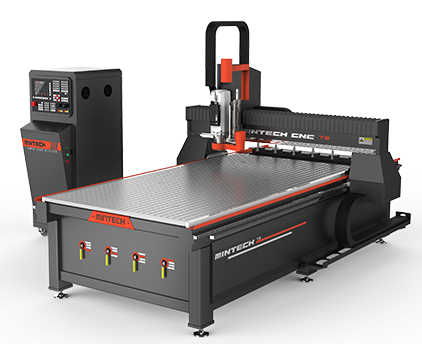

The pp sheet cutting machine is a kind of cutting equipment that we commonly use now. It can cut but not limited to the cutting machine pp sheet. The sheet processed by the sheet cutting machine has a more excellent performance ability. With the development of the modern machinery processing industry, the requirements for cutting quality and precision are constantly improving, and the requirements for improving production efficiency, reducing production costs, and having high-intelligence automatic cutting functions are also increasing. Today, let's take a look at the instructions of our pp sheet cutting machine.

1. After the cutting machine is installed, turn on the power to check whether the rotation of each part of the machine is flexible and whether the fasteners are loose.

2. Turn on the power, press the button of the host, and check whether the direction of the blade is consistent with the direction of the arrow. If it is reversed, adjust immediately. After the inspection is completed, the rock sample can be clamped for cutting. When the rock sample is clamped, a reliable clamping point should be selected to prevent virtual clamping and false clamping. In order to avoid damage to the tool and rock sample due to rock movement during the cutting process.

3. When working, start the main motor first, and then press the work feed button. When starting to cut, because the rocks are often irregular in shape, the feed speed should be slow at this time, and the blade can be faster after all the blades enter the rock sample. .

4. The cutting machine automatically advances and retreats the knife. When the cutting knife moves to the end along the worktable, it can automatically retreat to the beginning and automatically stop moving. If you need to go back during work, just press the fast back button on the console. In fast rewind, you need to advance, and you can also advance by pressing the work advance button. Regardless of whether the knife is in or out, the knife can stop moving by pressing the stop button. When working, if you find that the cutter is far away from the rock sample, you can press the fast forward button (press and hold) or jog to fast forward. When the blade is close to the rock sample, release the button. Then press the work-in button again to perform normal cutting. This can shorten the feed assist time.

For specific details, please call our service hotline: 138-2577-9334. Mintech Electronics fundamentally solves technical problems in the field of sheet metal processing such as aluminum alloys and engineering plastics, thereby continuously promoting the technological upgrade of processing equipment; it is currently a domestic technical model industrial-grade CNC processing equipment manufacturer. Welcome to consult.