With the development of modern machinery, major manufacturers and customers have become more and more strict with the requirements of the plate. Therefore, the aluminum plate engraving machine has become more and more known to the public, but you may not know the correct use and operation of the machine, so today let's take a look at the use of aluminum plate engraving machine .

1. Check the machine and fix the workpiece correctly: check whether there are debris on the machine tool, especially stone particles, large-area stone powder, sand, etc., pay attention to cleaning, otherwise it will easily affect the flatness of the material. Place the workpiece according to the placement direction in the typesetting programming software, depending on whether the material is placed horizontally or vertically. Note that the material and the machine are parallel to the direction of the axis, and do not put it off. Use the pressure plate to fix the material, the general fixing methods are pressure and upper two. When pressing with a pressure plate, please be careful not to press the processed part of the material to prevent mechanical collision or tool collision.

2. Determine the origin of the workpiece coordinate system, which is what we often call tool setting. Align the origin of each axis of the machine with the original point, and then return the data to zero or enter the coordinates of the corresponding coordinates.

3. Detect water spray and water circulation, adjust mechanical speed and feed speed, and simulate in the aluminum plate engraving machine control system.

4. Start the engraving machine.

5. Processing is completed. Confirm whether the engraving effect is satisfactory, and whether it is necessary to make up the knife.

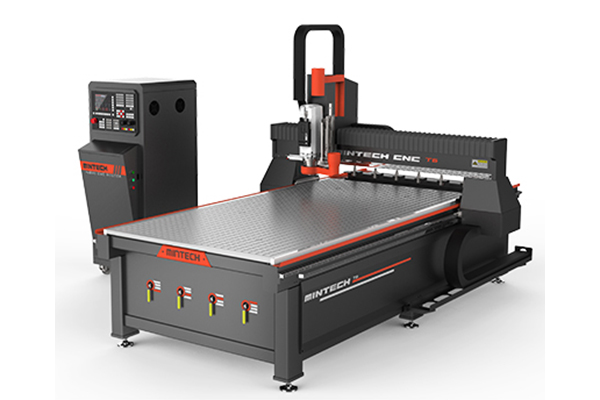

The aluminum plate engraving machine is a professional CNC machine tool developed by our Mintech Electronics. It is a set of plate engraving machine equipment. Therefore, we must strictly abide by the use process to avoid damage to precision instruments and result in processed products. error. For specific details, please call our service hotline: 138-2577-9334. Welcome to consult us.