- 产品描述

Mintech MS3200

Acrylic electronic sawing material

Features:

-

- Performance characteristics: fast cutting speed, high cutting precision, simple operation, high safety factor, good dust collection effect

- Adapt to the board: acrylic, wood, various plastic materials, electronic insulation materials, bakelite, aluminum-plastic panels, etc.

- Industry application: acrylic processing, light guide plate production, woodworking furniture, PCB circuit board, engineering plastics industry, etc.

Mechanical specifications

- Model: MS-3200

- Dimensions: 5600×5800×1700mm

- Cutting size: 3300×3300mm

- Cutting thickness: ≦80mm

- Main saw blade: outer diameter Ø250mm-400mm, shaft diameter: 30mm

- Slot saw blade: outer diameter 200mm, shaft diameter: 30mm

- Cutting accuracy: ±0.1mm (except for material deformation)

- Machine power: 21KW

- Power requirements: 380V 60HZ 40A

- Gas supply requirements: 5-6Kg/cm²

Basic configuration instructions

- 1. Feeding platform:

(1) It is composed of two parts, one is the roller bracket structure, the other is the air-bearing table structure, and the air-bearing table structure is mainly to ensure the stability of the feeding when cutting small materials

(2) with There are nine grippers, servo numerical control positioning, precision rack drive, servo drive;

(3) The design of this platform effectively guarantees the accuracy of pushing the material, and does not run off to prevent the sheet from scratching. .

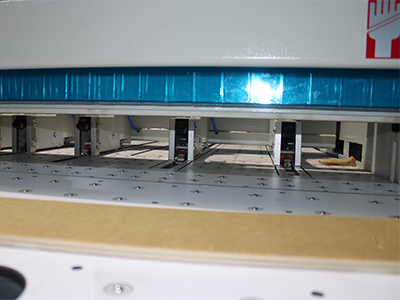

- 2. Material pressing mechanism: Double pressing beam mechanism prevents the sliding of the plate, guarantees the cutting precision and cutting effect of small and thin materials, and avoids edge chipping when cutting ultra-thin materials (especially for optical-grade light guide plates) .

- 3. Saw car structure: assembly main saw and slot saw, helical rack and linear guide drive, servo drive; main saw slot saw positive and negative sawing, to avoid plate edge burst and damage to the protective film, to ensure the quality of cutting; The rack and linear guide rail drive ensure the straightness of cutting.

- 4. Water mist cooling: cooling the saw blade and cutting surface when cutting hard or thick materials

- 5. Front countertop: air-floating platform, reducing friction between feeding and discharging, easier loading and unloading, preventing sheet scratches

- 6. Control system: Mitsubishi PLC control, Delta touch screen man-machine interface; simple operation, easy to use, stable performance

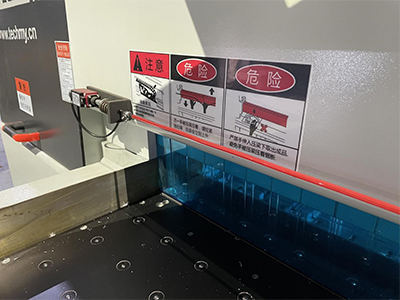

- 7. Safety protection: air pressure alarm, stop working when the air pressure is insufficient; the operating space is equipped with an infrared protection line, when the operator enters the protection area while working, the machine will stop working; the main saw and slot saw are fully enclosed, and the protective cover is opened, The machine will stop working

- 8. Dust collection device: under the saw car is a crawler-type dust suction trough. There are suction ports on the left and right ends of the machine, and there are also dust suction ports above the pressure beam. The multi-directional dust collection design can achieve 90% dust treatment effect. above

- 9. Material supporting mechanism: the plate smaller than 500mm is equipped with a unique supporting mechanism, and the narrowest and reliable material width is 50mm to avoid the deviation of small plates during the feeding process.

Machine configuration table

|

Sawing capacity |

Cutting length |

3300mm |

|

|

Sawing thickness |

Up to 80mm |

|

|

|

Sawing width |

3300mm |

|

|

|

Main saw blade |

Main saw blade diameter |

250~400mm |

|

|

Saw shaft diameter |

30mm |

|

|

|

Main saw shaft speed |

0~4000 rpm adjustable |

|

|

|

Vice saw blade |

Main saw blade diameter |

200 mm |

|

|

Saw shaft diameter |

30mm |

|

|

|

Vice saw blade speed |

6000 rpm |

|

|

|

Saw seat |

Forward stroke speed |

0~100 m/min adjustable |

|

|

Backward speed |

110 m / min |

|

|

|

motor |

Main saw blade drive motor |

11KW(AC Servo motor) |

|

|

Vice saw motor |

1.5KW |

|

|

|

Saw base drive motor |

2KW |

|

|

|

High pressure blower motor |

2.2KW*2 |

|

|

|

Automatic feeding system |

1.5 KW (AC Servo motor) |

|

|

|

other |

Small feed |

Standard configuration, the narrowest material width is 50mm |

unique design |

|

Feeding mechanism |

The air-bearing table is 600mm wide, special for placing small materials |

||

|

Roller bracket, large slab cutting material |

|||

|

Pressure beam |

Double-pressure beam structure solves the problem of easy edge chipping when cutting thin materials |

||

|

Front-end platform |

Full table air float beads |

|

|

|

Automatic feeding speed |

80 m / min |

|

|

|

Use air pressure |

5-6 kg/c㎡ |

|

|

|

Height of workbench above ground |

940 mm |

|

|

|

Work folder (number of work folder) |

9 |

|

|

|

computer program |

touch screen |

|

|

|

Net weight/Gross weight |

5500KG |

|

|

|

Mechanical size (length*width*height) |

5600*5800*1700 |

|

|

|

Configuration |

PLC |

Mitsubishi Japan |

|

|

Contactor |

Schneider |

|

|

|

touch screen |

Taiwan Delta |

|

|

|

Feeding servo |

Taiwan Delta |

|

|

|

Gas line |

Adek |

|

上一篇:没有了