- 产品描述

Mintech MC2500

RF laser cutting machine

Features:

-

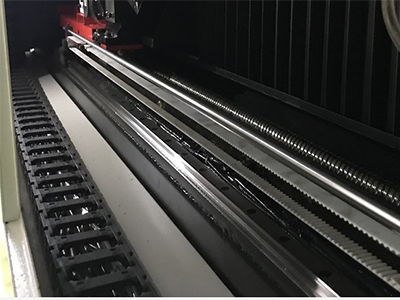

- Performance characteristics: steel pipe welding structure, aluminum profile precision milling guide surface, servo drive, screw drive, high precision and high quality cutting

- Adapt to the board: acrylic, various plastic materials, electronic insulation materials, wood boards and other non-metallic boards

- Industry applications: Acrylic products, architectural decoration, craft gifts, electronic films, fabrics and leather materials, etc.

Mechanical specifications

- Model: MV-2500

- Working voltage: AC220V / 50HZ / 2PH

- Machinable size: 1250 mm ×2500 mm

- Maximum processing speed: 20 m/min

- Repeat positioning accuracy: + /-0.05mm/300mm

- Laser: use imported radio frequency lasers such as Rofin

- Drive mode: X, Y and Z axes are driven by high-precision ball screws.

Laser

- Using German Rofin RF laser

- Sealed-off CO₂ laser, combined with two-axis or three-axis flight optical path technology, opens up a new application field for non-metallic materials processing

- The Rofin series laser light source has excellent beam quality. Even if it is a very large-format processing or a long focal length, the size of the laser spot reaching the surface of the material is still very small (= high energy density). This is the basis for precision and rapid processing. StarShape has a variety of configuration possibilities. According to the actual application situation, the processing format and the related spot size can be precisely adjusted through the control software. Therefore, the most ideal production speed can be achieved.

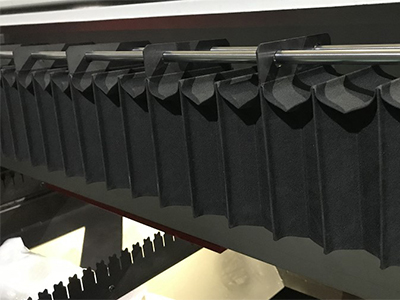

Flight system

- Constant light path design ensures that the laser energy of each focus point is consistent on the large-format work surface to avoid uneven light intensity.

- The light path dust-proof device prevents the flying light path from contacting the outside air, as far as possible to ensure the cleanness of the laser lens, and improve the light guide efficiency

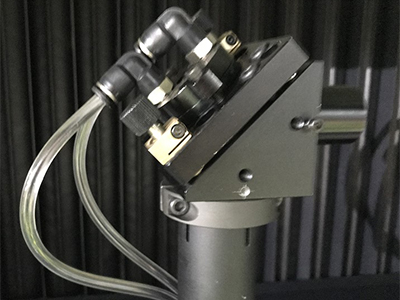

- Optical lens cooling method: water cooling, to prevent the heating of the lens from affecting the light guide and the service life of the lens

Low light cooling system

- Adopt industrial-grade water-cooling controller, intelligent constant temperature control, water temperature can be controlled at ±0.5°; configuration of over-temperature and water pressure alarm

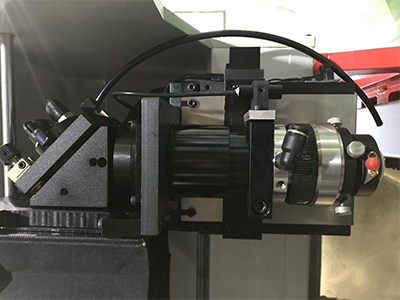

Cutting head

- Independent research and development, fast switching of lenses with different focal lengths, infrared positioning

Machine configuration table

|

Configuration name |

describe |

Remark |

|

Laser power |

Rofin RF laser |

Optional 180W, 250W, 350W, 550W |

|

Dimensions |

4000×2000×1300mm |

|

|

Processing stroke |

X:1300,Y:2500mm |

MV3000 type 1500 × 3000mm |

|

working desk |

Triangular aluminum support |

|

|

Alignment device |

infrared |

|

|

the fastest speed |

20m/min |

Fastest |

|

Acrylic maximum cutting thickness |

40mm |

Perfect cut |

|

X/Y axis positioning accuracy |

±0.05 |

mm/m(mm/m) |

|

X/Y axis repeat positioning accuracy |

±0.05 |

mm |

|

Cutting head |

Fast switching between long focus and short focus |

Independent research and development |

|

Focus adjustment |

electric |

|

|

Mechanical transmission system |

X/Y axis adopts ball screw |

Taiwan imports |

|

X/Y/Z adopts TBI guide rail |

Taiwan imports |

|

|

Dedicated cooling system |

Temperature control accuracy is up to ±0.5℃, multiple alarm protection functions: |

Special domain |

|

Light path system |

Flying optical path, sealed and dust-proof |

|

|

Optical lens cooling system |

|

|

|

Exhaust system |

Smart partition start exhaust |

|

|

sport control |

Ruida CO² CNC System |

|

|

Support software |

CAD, Coredraw, etc. |

|

|

server Driver |

MITSUBISHI |

Mitsubishi Japan |

|

HMI |

High-resolution capacitive touch screen |

FLEXEM |

|

Fan control |

Touch screen one-touch control |

Autonomous configuration |

Processing case

上一篇:没有了

下一篇:没有了