- 产品描述

Mintech MS2600

Electronic sawing material

Features:

-

- Performance characteristics: fast cutting speed, high cutting precision, simple operation, high safety factor, good dust collection effect

- Adapt to the board: acrylic, wood, various plastic materials, electronic insulation materials, bakelite, aluminum-plastic panels, etc.

- Industry application: acrylic processing, light guide plate production, woodworking furniture, PCB circuit board, engineering plastics industry, etc.

Mechanical specifications

- Model: MS-2600

- Dimensions: 5100×5100×1700mm

- Cutting size: 2500mm ×2500 mm

- Cutting thickness: ≦60mm /min

- Main saw blade: outer diameter Ø355mm, shaft diameter: 60mm + /

- Slot saw blade: outer diameter 180mm, shaft diameter: 50mm + /

- Cutting accuracy: ±0.1mm (except for material deformation) + /

- Machine power: 15KW

- Power requirements: 380V 60HZ 40A

- Gas supply requirements: 5-6Kg/cm² m

Basic configuration instructions

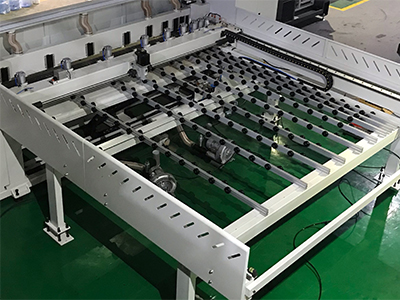

- 1. Feeding platform: air-floating table, equipped with gripper, servo numerical control positioning, screw drive, servo drive; the design of this platform effectively guarantees the accuracy of pushing and prevents the sheet from scratching.

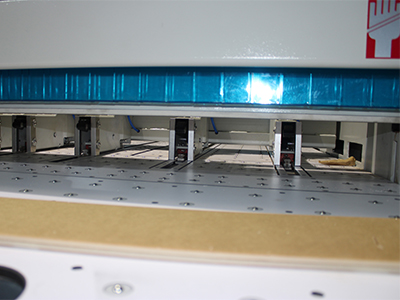

- 2. Material pressing mechanism: Double pressing beam mechanism prevents the sliding of the plate, ensuring the cutting accuracy of small and thin materials and the effect of the cutting surface; the plate smaller than 500mm is equipped with a unique supporting mechanism to avoid small pieces of plate Deviation phenomenon in the feeding process.

- 3. Saw car structure: assembly main saw and slot saw, helical rack and linear guide drive, servo drive; main saw slot saw positive and negative sawing, to avoid plate edge burst and damage to the protective film, to ensure the quality of cutting; The rack and linear guide rail drive ensure the straightness of cutting.

- 4. Water mist cooling: cooling the saw blade and cutting surface when cutting hard or thick materials

- 5. Front countertop: air-floating platform, reducing friction between feeding and discharging, easier loading and unloading, preventing sheet scratches

- 6. Control system: Mitsubishi PLC control, Delta touch screen man-machine interface; simple operation, easy to use, stable performance

- 7. Safety protection: air pressure alarm, stop working when the air pressure is insufficient; the operating space is equipped with an infrared protection line, when the operator enters the protection area while working, the machine will stop working; the main saw and slot saw are fully enclosed, and the protective cover is opened, The machine will stop working

- 8. Dust collection device: under the saw car is a crawler-type dust suction trough. There are suction ports on the left and right ends of the machine, and there are also dust suction ports above the pressure beam. The multi-directional dust collection design can achieve 90% dust treatment effect. above

Machine configuration table

|

Project Description |

Model specification |

|

PLC controller |

Mitsubishi |

|

Drive/Servo Motor |

Delta |

|

Human Machine Interface |

Delta |

|

Frequency converter |

Mid-drive |

|

Main motor |

National standard |

|

Rail/slider |

Taiwan |

|

Pneumatic Components |

Airtac/Asahi |

|

Equipment size (length/width/height) |

5100/5100/1700mm |

|

Actual cutting length (length/width) |

2500×2500mm |

|

Sawing thickness |

80mm |

|

Main saw blade diameter |

355mm |

|

Main saw blade shaft diameter |

60mm |

|

Main saw blade speed |

4000rpm (adjustable) |

|

Slot saw blade diameter |

180mm |

|

Slot saw blade shaft diameter |

50mm |

|

Slot saw blade speed |

6500rpm |

|

Saw base forward speed (infinite) |

0-120m / min |

|

Saw seat retreat speed |

100m/min |

|

Main saw motor (national standard) |

7.5kw |

|

Slot saw motor |

1.5kw |

|

Saw base drive servo motor |

1.5kw |

|

Automatic feeder |

1.5kw |

|

Pushing servo motor |

1.5kw |

|

High pressure blower motor |

4kw |

|

Automatic feeding speed |

0-120m / min |

|

Use air pressure |

5-6kg/cm |

|

Height of workbench above ground |

910mm |

|

net weight |

3500kg |

下一篇:没有了