- 产品描述

V8

CNC machining center manual

Features:

-

- Performance characteristics: complete functions, good engraving and cutting effect, high precision, cost-effective processing tool for high-quality processing

- Adapt to the board: acrylic, various plastic materials, electronic insulation materials, bakelite, copper-aluminum panels, aluminum-plastic panels, etc.

- Industry applications: acrylic products, advertising production, tooling and fixtures, engineering plastics, aluminum processing industries, etc.

Working voltage: AC380V/50HZ/3PH

Machinable size: 1270mm*2540mm*100mm

Distance from beam to table surface: 200mm

Z-axis stroke: 450mm

Maximum processing speed: 20m/min (tool coordination is required for maximum cutting)

Maximum idle movement Speed: 30m/min

Repeat positioning accuracy: +/-0.05mm

Drive mode: X, Y, Z axis are driven by high-precision ball screws.

V8 series gantry machining center, more than 15 years of industry application, industry-leading design, excellent and reliable performance.

The use of high-quality components and the use of machine tools can maintain high precision for a long time.

The machine tool components adopt FEM (Finite Element Analysis and Calculation), and the unique design guarantees to reduce vibration.

Safety assurance

-the machine tool is designed according to the American AMT machinery manufacturing standard.

--The electrical standard adopts EMC electrical standard design.

--All moving parts have safe and reliable protection devices.

--Operation status monitoring.

--X, Y and Z three-axis transmission systems are equipped with a variety of safety protection control devices, such as electrical control limit, software limit and mechanical limit to ensure the safety of machine tool work.

After-sales service

--Dongguan Mintech Electronics Co., Ltd. online service system

--Dongguan Mintech Electronics Co., Ltd. technical support

When a customer requests service, the company will respond within 24 hours of receiving the customer's request. If necessary, arrange technicians to solve the equipment failure within 24 hours.

Tool compensation function. Support tool radius compensation and length compensation through manual and automatic two modes of measurement, easy-to-understand human-computer interaction interface, allowing users to reduce the conversion of tool compensation values. For users who use tool length compensation, many unnecessary conversions are avoided.

Program simulation and real-time simulation. Provide a powerful program simulation function, which can fully display the process of blank cutting. The program simulation function also supports the switch between the simulation interface and the processing interface at any time, which is convenient for users to monitor the processing program in real time and make processing more convenient.

One-time clamping completes the precise machining of functions such as milling, drilling, and chamfering.

The use of high-precision ball screws, guide rails, rack and pinion to ensure the stability of the machine tool.

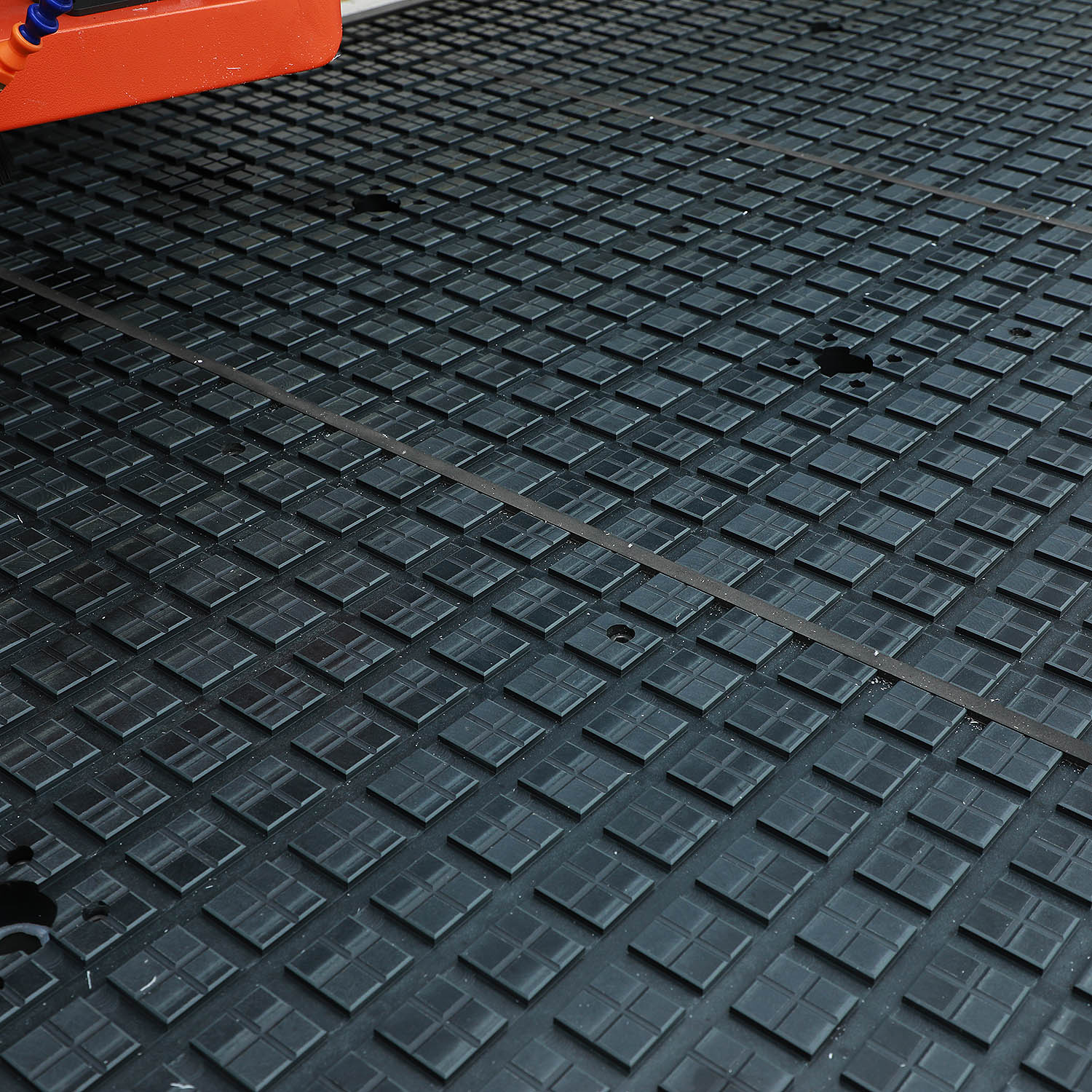

Vacuum adsorption table, fast clamping.

|

Spindle Speed: 4000-24000RPM

Chuck Specification: SK16

Cooling Method: Use maintenance-free independent fan cooling to reduce maintenance

Spindle noise: idling less than 65 decibels

Adopting a high-efficiency grid-shaped vacuum table, any part of the worktable can quickly adsorb the workpiece.

Due to the extremely high vacuum switching frequency, in order to improve the service life and reduce the failure, the solenoid valve

is used to control the vacuum pipeline and the double filter is used to avoid the vacuum pump sucking the chips. Cause malfunction

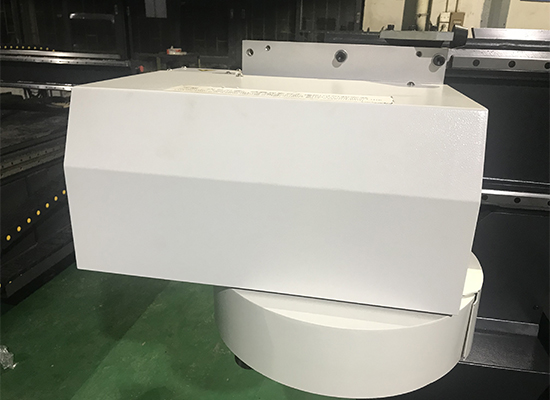

tool change speed block, with protection function to prevent dust and misoperation, avoid tool change failures. The

tool magazine is installed on the cross beam and effectively reduces tool changes. During the process, the work surface moves to reduce unnecessary movement and prolong the life of the machine.

|

Machine configuration list

|

NO |

content |

|

Specification |

Remark |

|

1 |

Processing range |

X axis processing range |

1270mm |

|

|

Y axis processing range |

2540mm |

|||

|

Z axis processing range |

200mm |

|||

|

2

|

Machine parameter index

|

X, Y, Z axis motion positioning accuracy |

0.05mm |

The above position parameters refer to the international ISO230-2 and are calibrated using RENISHAW laser interferometer. Note (1) |

|

X, Y, Z repeat positioning accuracy |

0.05mm |

|||

|

Maximum moving speed |

30m/min |

|||

|

Maximum processing speed |

20m/min |

|||

|

Total weight of machine tool |

About 2500KG |

|||

|

Working voltage of machine tool |

AC380V/50HZ/3PH |

|||

|

3 |

Workbench |

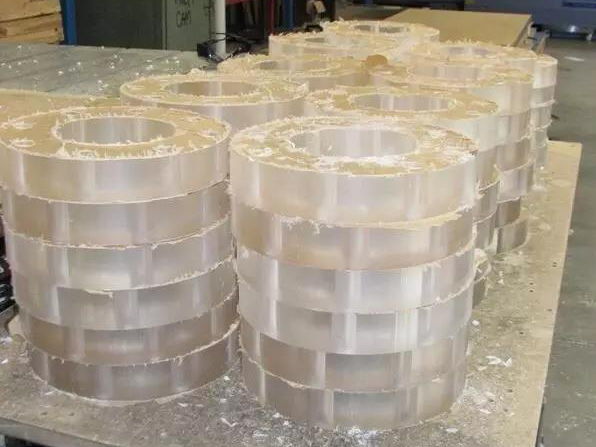

Phenolic Panel Workbench |

Vacuum adsorption table |

|

|

Workbench load |

500KG |

|||

|

4 |

CNC system |

Weihong Professional CNC System |

NK280 |

|

|

5 |

Tool change system |

Disc |

8 pockets |

Taiwan |

|

6 |

Drive power (AC servo) |

X axis drive motor |

850W |

Japan |

|

Y axis drive motor |

850W |

Japan |

||

|

Z axis drive motor |

850W |

Japan |

||

|

Voltage |

AC380/3PH |

|||

|

7 |

Electric spindle (frequency conversion) |

Spindle |

Air-cooled |

|

|

Spindle speed |

4000—24000RPM |

|||

|

Spindle power |

9KW |

|||

|

Spindle taper |

ISO30 |

|||

|

Spindle dynamic balance level |

G2.5 |

|||

|

Frequency converter |

VFD |

|||

|

8 |

guide |

X axis guide |

Square rail (25mm) |

|

|

Y axis guide |

Square rail (35mm) |

|||

|

Z axis guide |

Square rail (25mm) |

|||

|

9 |

transmission |

X axis transmission |

Ball screw rod |

|

|

Y axis transmission |

Ball screw rod |

|||

|

Z axis transmission |

Ball screw rod |

|||

|

Note (1): |

Positioning accuracy detection method: the arrangement of measurement data adopts mathematical statistics method. That is, select any number of positioning points (usually 5-15) along a certain measurement axis parallel to the coordinate axis, and then repeat positioning for each positioning point (usually 5-13 times). You can approach the positioning point in one direction, or approach from two directions separately, and then perform statistical processing on the measurement data to obtain the arithmetic average. Furthermore, the mean deviation, standard deviation, and degree of dispersion are obtained. Dispersion represents repeated positioning accuracy. It and average deviation together constitute positioning accuracy. The sum of the two is the maximum positioning deviation that can be achieved when positioning between any two points. |

|||

Applications